Turbos: Not just a lot of hot air

Was there ever another season like 1985 in F1? It was a season of almost undriveable machines, that frequently ran out of fuel.

The art of aerodynamics was creating cars that could corner at remarkable speeds, and drivers of the calibre of Ayrton Senna (pictured) and Nigel Mansell were appearing on the top step of the podium for the first time.

And, of course, it was the golden era of turbocharged engine madness.

These days, every engine in F1 has to be turbocharged, allowing (or forcing, depending on your viewpoint) manufacturers to extract greater power from smaller cylinders.

But it was not always thus. Turbos have been around since the end of the 1800s but didn’t make an appearance in F1 until 1977 and, even then, they were utterly unreliable.

But, as is the way with F1, great minds were working on solving the problems with turbocharged engines, and innovative solutions began to appear. By the mid-80s, turbos were untouchable and producing huge amounts of power – but their success would eventually lead to them being banned.

Turbocharging has forced F1 to innovate on a huge scale – here are just three changes that have made a difference.

The engines canna take it

As Scotty (never) said in Star Trek, when turbos were introduced to F1, the engines could not take it, and expired again and again and again.

Renault’s RS01 (pictured) was the first turbo-powered car, and made its maiden appearance at the 1977 British Grand Prix. It blew up in the middle of the race, as it did at every other race that season.

A basic turbo consists of a turbine which is spun by a car’s exhaust gases; that spinning turbine powers a compressor, which squeezes more air into each engine cylinder, helping produce a bigger bang and more power.

The trouble is, producing a bigger bang in each cylinder puts huge additional stresses on an engine, including greater explosive forces and higher operating temperatures.

Before Renault could make a race-winning engine, they first had to build an engine that could actually finish a race. And to do that, they had to make sure every part of the engine was as near perfect as possible.

And so, while it appeared few major breakthroughs were being achieved in the early years of turbocharging, the reality was that Renault and its suppliers were engaged in a constant struggle to innovate and make the core engine better, stronger and more reliable.

Bernard Dudot, who was in charge of Renault’s technical programme, said: ‘At first we needed to put the suppliers at the right level of service – for example the guys supplying the pistons, valves and so on. We needed to improve quality control.’

As part of this drive to improve the basic engine, advances were made which would have a huge impact on the sport in the years ahead.

For example, Renault introduced pneumatic valves on later versions of their V6 turbo, in 1986, using compressed nitrogen to control valve position rather than a coiled spring. Even the best traditional springs couldn’t survive more than 15,000 rpm, whereas pneumatic valves allowed engines to be produced which would rev up to 19,500rpm and, theoretically, beyond.

These days, engines are restricted to 15,000rpm, helping make them far more reliable but, perhaps, just a tiny bit less exciting to listen to.

The arrival of twins

The early turbo cars were not just unreliable, they were horrible to drive.

They suffered badly from turbo-lag – when a driver tried to accelerate, it would take a little time for the exhaust gasses to spin the turbo up to speed. As a result, there was a delay before the engine was fed with properly compressed air and acceleration was woefully compromised.

At its worst, the delay between pressing the accelerator and the engine delivering full power could be almost two seconds, and so drivers had to brake early, then hit the accelerator early in a corner so the car would deliver full power as they exited the corner.

As an added challenge, when the power did finally arrive, it arrived with a thump and it was all too easy to lose traction and spin the car.

At the 1979 Monaco Grand Prix – at a circuit where acceleration is supremely important – Renault debuted their twin-turbo engine. Although they scored no points in Monaco, the following race in France saw Renault finally post a historic first and third position finish, on home territory (with a French driver, powered by French fuel and driving on French tyres, for good measure).

Twin-turbo technology had finally made the cars driveable and, although reliability issues would continue to plague Renault for years to come, they had shown that it was possible for a turbo-powered car to win a grand prix. Other teams took note, and the turbo era began in earnest.

So what was the secret of Renault’s twin turbo? Instead of one big turbo unit, with a heavy turbine that took an age to spool up, Renault used two smaller turbos, one per cylinder bank.

Because these were lighter, they spooled up much more quickly. Drivers Jean-Pierre Jabouille (pictured) and René Arnoux didn’t recognise their engines’ performance characteristics, such was the improvement in throttle response times and power delivery.

Renault and other teams could finally put the power of their turbo cars to use and, indeed, boost that power more and more.

By 1981, Renaults were producing 540bhp, but that was just the beginning. Another 50bhp arrived the following year and then, by the middle of the decade, their cars were pumping out 1,200bhp in all-out qualifying mode and others were managing even more, an estimated 1,400-1,500bhp from the BMW-powered Brabhams of the time.

These were ‘grenade’ engines, so-called because they blew up after a few laps in quali mode.

Powerful as they were – and they remain the most powerful in F1 history – these engines would have been unusable without innovations such as the twin-turbo, which allowed drivers to harness the astonishing amounts of energy being produced.

Split ends

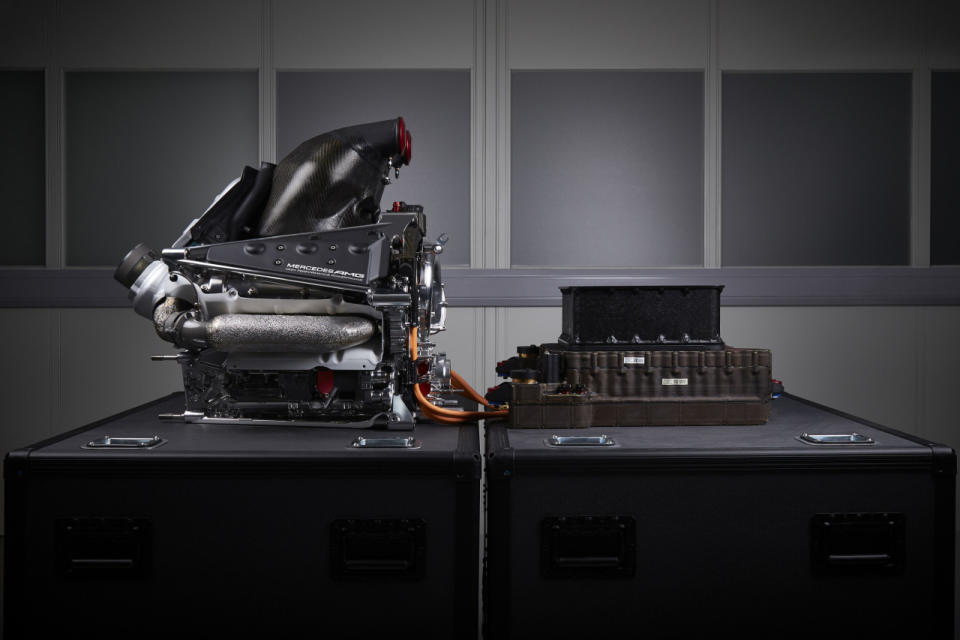

A more recent turbocharger innovation came from Mercedes when turbos returned to F1 in 2014.

They split the turbo into its two key components and then put one at each end of the engine (pictured), joined by a shaft running down the middle.

So the turbine – which gets very hot thanks to those 900C-1,000C exhaust gases – is kept well away from the compressor, which works best when things are cool.

Less pipework is needed, a smaller intercooler can be used (so the car’s more aerodynamic) and the whole thing is much more efficient than a traditional all-in-one turbo unit.

Sounds simple, doesn’t it? Well, Mercedes started work on the design back in 2011.

According to Mercedes engine boss Andy Cowell, about 600 CFD simulations (Computational Fluid Dynamics… think big computer programmes which examine how gases behave) were undertaken simply to get the initial design work under way.

The next time you feel like complaining about Mercedes’ mechanical dominance in F1, dwell on those figures. Their innovative approach has taken years of hard work and countless man-hours… and they’ve earned their place at the top.

Yahoo Sport

Yahoo Sport